Teams will develop new electrochemical interface materials for batteries, corrosion-resistant coatings

May 13, 2022

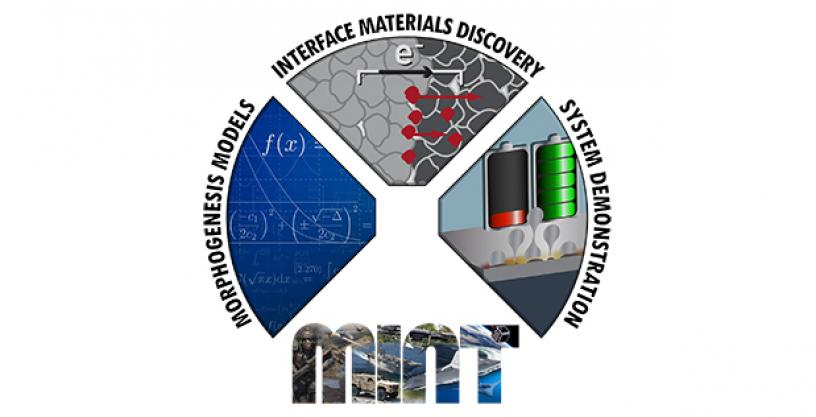

DARPA has selected six teams of industry and university researchers for the Morphogenic Interfaces (MINT) program. MINT aims to enhance the performance and persistence of batteries, anti-corrosion coatings, and other electrochemical systems that power and protect critical Department of Defense hardware and platforms.

The teams will develop novel solid-solid electrochemical interfaces for solid-state batteries and solid-liquid interfaces for corrosion-resistant coatings. The inspiration for pursuing novel, adaptive electrochemical interfaces comes from biology and the concept of morphogenesis, which captures the physics behind how cells and tissues take shape.

“Current solid-state batteries that have high energy density have limited charge/recharge cycles and current corrosion-resistant coatings require frequent maintenance in aggressive performance environments,” said Vishnu Sundaresan, MINT program manager in DARPA’s Defense Sciences Office. “Premature failure in these systems is due to the formation of structural defects such as voids at the interfaces between two materials. The teams we’ve selected will develop and demonstrate novel morphogenic interface materials to enable long-lasting and high-performance solid-state batteries that power everything from warfighter battery packs to unmanned aerial and ground vehicles as well as provide low-maintenance corrosion resistant coatings for critical maritime assets deployed in harsh environments.”

The following research teams are on contract to pursue a variety of approaches within the program’s two focus areas:

Solid/solid charge transfer interfaces for solid-state batteries

- GE Research, teamed with the University of Michigan, University of California Santa Barbara, and Storagenergy, will develop a multi-scale integrable deep neural network model to design an intermetallic solid/solid charge transfer interface material to enhance the performance of lithium-ion solid-state batteries (Li-SSBs).

- Carnegie Mellon University, teamed with MIT, Harvard University, Argonne National Laboratory, 24M Technologies, and QuantumScape, will develop an end-to-end model for solid-state batteries using differentiable physics to discover new soft solid materials and demonstrate its application in Li-SSBs.

- University of Illinois Urbana-Champaign, teamed with University of Michigan, Purdue University, Princeton University, Caltech, Georgia Tech, and Xerion Advanced Battery Corp., will develop a chemo-mechanical model of solid/solid interfaces using atomistic, molecular dynamics and continuum models and use this knowledge to design and fabricate Li-SSBs containing novel interface materials.

Solid/liquid and solid/vapor interfaces for corrosion resistant coatings

- Johns Hopkins University, teamed with Northwestern University and Northrop Grumman Corporation, will develop thermodynamic, quantum mechanical, and dynamic models to explore self-organized titanium-chromium (Ti-Cr) coatings with a hierarchical microstructure that offer resistance to cracking and corrosion fatigue.

- University of Virginia, teamed with Saint Louis University and Florida State University, will develop physics-based design and control of material-environment interfaces to design anticorrosion surface treatments that extend the fatigue life of aluminum-magnesium (Al-Mg) and magnesium-aluminum (Mg-Al) alloys.

- GE Research, teamed with University of Virginia, DNV GL USA, and Brigham Young University, will explore the design of high entropy alloy coating via atomic, electrochemical models and physics-based machine learning that use controlled corrosion of surface treatments to form a protective barrier film.

The initial challenge for program performers in both focus areas during Phase I will be to model interfacial processes (i.e., address the performance-degrading microscopic irregularities that form at the interfaces of electrochemical materials), design and discover morphogenic interfaces, and demonstrate the performance improvements due to the morphogenic interface in a solid-state battery and for corrosion mitigation of structural alloys. In Phase 2, the teams will improve upon their models to increase accuracy and improve the performance of interface materials in batteries and corrosion protection.

###

Media with inquiries should contact DARPA Public Affairs at outreach@darpa.mil

Associated images posted on www.darpa.mil and video posted at www.youtube.com/darpatv may be reused according to the terms of the DARPA Usage Policy.

Tweet @darpa