Program develops new design tools to exploit advanced materials and manufacturing technologies

Jan 15, 2021

DARPA’s TRAnsformative DESign (TRADES) program, which began in 2017, set out to develop foundational design tools needed to explore the vast space opened by new materials and additive manufacturing processes commonly called 3D printing. The program recently concluded having successfully developed new mathematics and computational techniques, including artificial intelligence and machine learning, that will allow future designers to create previously unimaginable shapes and structures of interest to defense and commercial manufacturing.

Manufacturing technology breakthroughs in recent years, such as 3D printing, have allowed precise material placement, new material behaviors, and complex shaping of parts and structures. Design tools, however, have not kept up with complexity of the design space resulting from these advances.

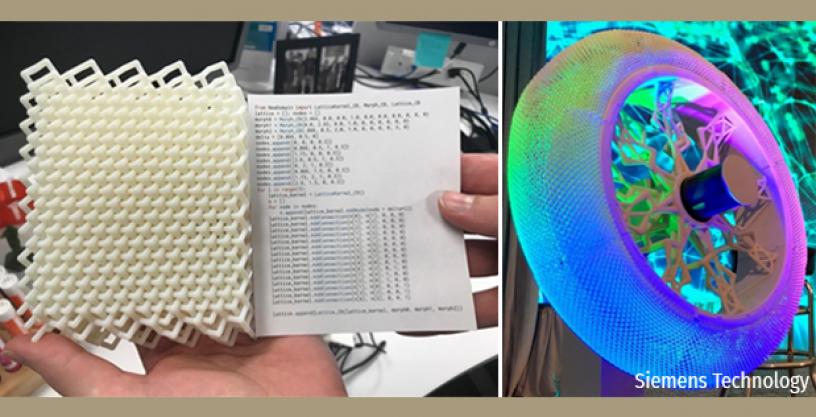

“In the past four years, TRADES has explored new ideas from mathematics and computer science that have allowed us to now represent things – like parts and components – that are a million times more complex than current state-of-the-art systems can represent,” said Jan Vandenbrande, program manager in DARPA’s Defense Sciences Office. “We can now describe both shape and material in a coordinated way across multiple physics to allow intricate designs and to understand properties at every point on the produced part. The aim is to be able to mimic integrated hierarchical structures found in nature, where different sized structures respond to different types of physics.”

TRADES tools are helping overcome what’s known as the “analysis interoperability problem.” Current processes involve describing a design and then analyzing it subject to multiple physics to answer questions such as: Is it strong enough? What’s its drag? What’s its thermal response? This process requires manual handling and transfer of data across incompatible systems.

“That manual handling, moving data from design systems to analysis, absorbs 50% of the entire design cycle because the formats are not compatible and current systems can’t directly interoperate,” Vandenbrande said. “TRADES has developed new concepts that would eliminate that bottleneck and accelerate the design process to include automated synthesis, where a computer explores design alternatives across multiple physics such as thermal, mechanical, electro-optic and the like, without human intervention. This would turn computers into true collaborative partners to help create new designs that are not intuitive to even the best human designers.”

TRADES is also enabling design for dynamic problems where structures change as time evolves, such as a solid-rocket engine, which changes its internal shape as the propellant burns.

“The TRADES design tools have made significant headway in addressing the time and cost burdens associated with current design cycles for DoD platforms and should enable rapid and effective response to new and evolving threats and requirements,” Vandenbrande said. “This includes generating in-field spares where shaping accommodates some of the discrepancies caused by material substitutions.”

The advanced design tools, processes, and algorithms developed in the TRADES program are poised to help increase the performance of DoD platforms; reduce the cost and time associated with materials and geometry selection, optimization, and numerical analysis; and enable exploration of new design concepts that are currently out of reach.

By enforcing generality in the underlying theories, TRADES is positioned to handle future 3D printing capabilities to include biological components such as a femur, including the “spongy” interior structures. Other challenge problems related to TRADES are available on http://solidmodeling.org/trades-cp/ to serve as future benchmarks.

The TRADES program comprised seven university and industry performers who created new design technologies focused on modeling, analysis, and synthesis: University of Colorado Boulder, Columbia University, Etaphase, International Computer Science Institute (ICSI), Palo Alto Research Center (PARC), Siemens, and University of Utah.

Two additional performers provided high-performance software and hardware testbeds on which the design technology teams developed and refined their tools: Sandia National Laboratory and the Texas Advanced Computing Center (TACC).

Although the program has formally wrapped up, a few performers are continuing work on their TRADES tools through 2021.

Photo Caption: TRADES tools allow representing designs a million times more complex than state-of-the-art design systems using only a few lines of computer code. Pictured on the left is a complex lattice structure with the code required to generate it. Similar code enabled generation of a lattice tire on the right, inspired by NASA’s spring tire. The TRADES tools open up a vast design space for DoD applications (photo credit: Siemens Technology)

# # #

Media with inquiries should contact DARPA Public Affairs at outreach@darpa.mil

Associated images posted on www.darpa.mil and video posted at www.youtube.com/darpatv may be reused according to the terms of the DARPA User Agreement, available here: http://go.usa.gov/cuTXR.

Tweet @darpa